Upgrade kits for various commercial heating and air conditioning applications are one of the most useful advancements of modern HVAC technology. They allow your customers to enjoy better capacity modulation of the system, enhanced temperature control, and improved humidity monitoring and control. Upgrade kits for compressors allow you and your technicians to outfit your customers with a device that grants them accurate control over various cooling and heating parameters that bring unparalleled performance, comfort, and convenience.

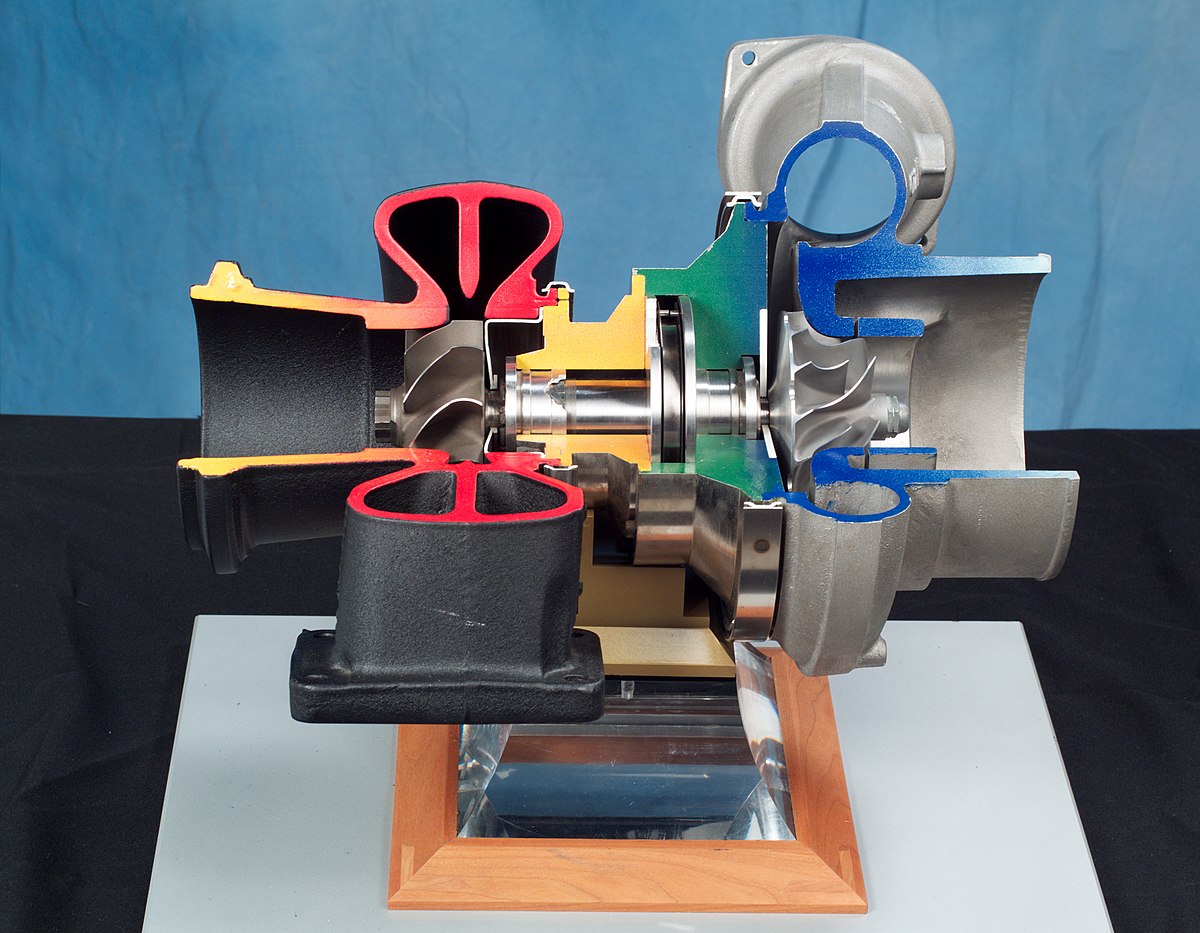

There are various upgrade kits for compressors currently available on the market, each with slightly different components, characteristics, and capabilities. In general, an upgrade kit features the coil, the thermistor, the valve, the replacement compressor, copper tubing, a comfort controller, and a controller and a networkable thermostat. However, knowing what a compressor upgrade kit is and what it contains is only the first step – you also need to be familiar with how to install it and how to prepare for the installation procedure.

What Is The Installation Process For Compressor Upgrade Kits?

Air conditioning compressor is a vital part of the majority of air conditioning systems. However, they can develop faults that require replacement. This is when you should advise your customers to also upgrade their compressors with an available kit and reap all the benefits of a more modern solution. First, let’s see what you should know when it comes to replacing, installing, and upgrading a compressor.

Identifying The Compressor Type & Shutting Down The Power

Ensure that you’re familiar with the compressor type your customers have before you offer a replacement. Prior to proceeding with the installation, first cut off all electrical supply into the unit to prevent serious injury.

Removing Refrigerant & Cutting Refrigerant Lines

Then, it’s time to open the system for cooling and remove the existing refrigerant. Current protocols for environmental protection dictate that you adequately dispose of the refrigerant by pumping it into a secure storage cylinder and not releasing it into the environment. After this, cut all refrigerant lines.

Removing The Compressor

After cutting the lines, slowly remove all the hoses that go into the compressor unit. Standard compressors have one bolt connecting them to the holding and the accessory bracket, so ensure you’ve unbolted it before beginning the replacement procedure.

Installing The New Compressor

Take the brand-new compressor, place it within the condenser, and use bolts to mount it. Then, reconnect all refrigerant lines again. Also, replace coils and all additional accessories and controls, since you’ll need to add new refrigerant to the system.

Reassembling The Unit

Finally, carefully reconnect the existing hoses and assemble the entire unit before moving on to reconnect and turn on the power source. Once this is done, take the time to test the system and ensure everything is in perfect working order.

What Do I Need To Assess Before The Upgrade?

The first and most important rule is to consult the manufacturer‘s official manual before beginning the compressor replacement procedure. There’s no better way to familiarize yourself with the best practices for each particular compressor upgrade kit than official information. However, if the manual isn’t available, keep the following considerations in mind before starting the installation:

- Make sure there is approximately 24 inches of space between obstructions and the compressor.

- Inspect the unit you’re installing, see whether it’s an upflow, downflow, or horizontal airflow unit, and ensure there’s enough space for proper air flow.

- Take the time to carefully inspect the proper wiring necessary for adequate compressor upgrade.

- Always follow the prescribed health and safety protocols and use all the necessary safety equipment.